Access to asset data for making informed decisions is the key for the operational performance. Artificial intelligence and predictive models are opening new areas of opportunities to build connected eco-system for enterprise asset management.

Challenges faced by enterprises

Assets are deployed remotely on field or in industry, for any service or periodic maintenance service technician visit the site location for the maintenance or service purposes. Assets pays a key role in the business operation and any downtime has a direct impact on the business revenue or subsequent process. In case of any problem first time fix rate plays an important role in asset service life cycle.

Asset manuals or knowledgebase is in silos and not easily accessible for the site technician on time.

Looking at these challenges coordinated approach is needed to improve on the asset performance and efficiency.

How to improve customer service with connected asset services

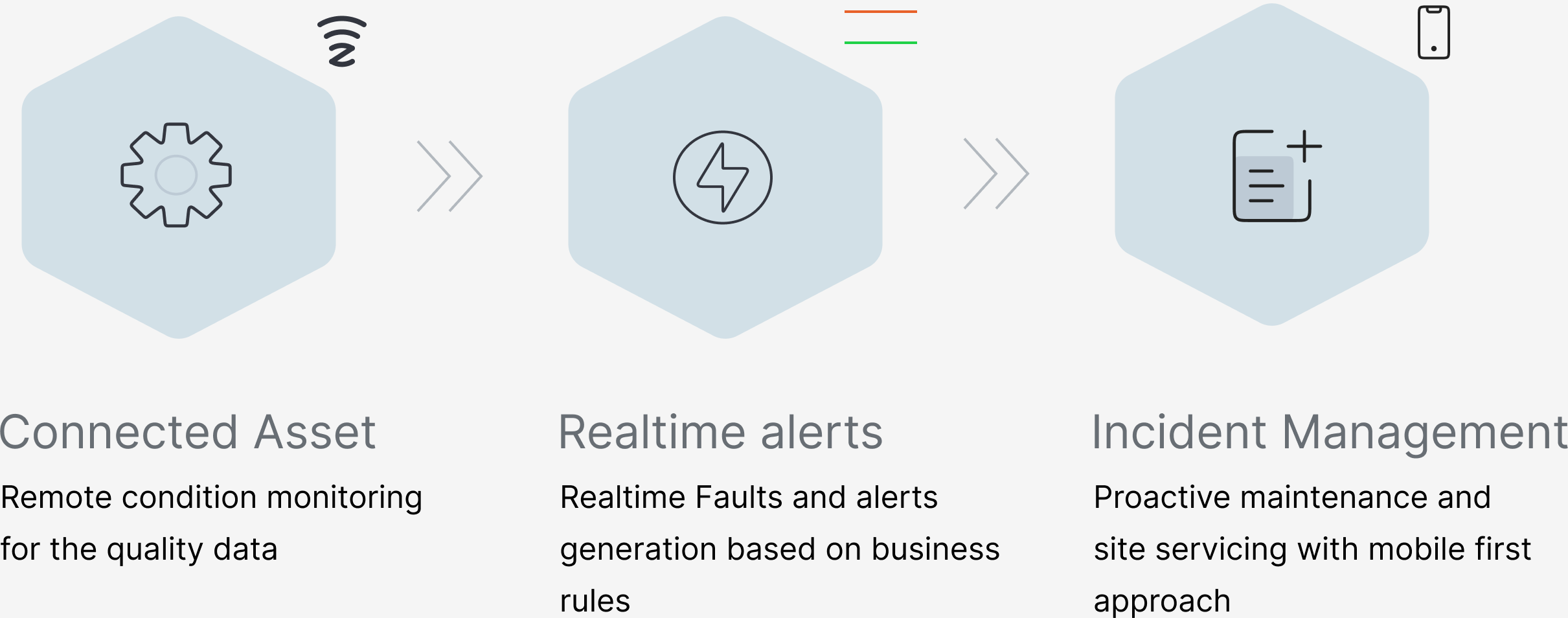

At the heart of this coordinated approach is free flow of information and concept of connected assets.

With connected assets, enterprises can bridge the gap between physical assets and information technology. Technology is helping to create a digital twin that’s digital representation of the physical asset. High quality reliable data collected from the physical asset help to get data insights and ability to apply different AI models on the data.

Data is new oil, enterprises should focus on bringing quality data in the data lake and apply different ETL models for business use cases.

Once enterprises has quality data different business rules can be applied to identify critical Faults or Alerts. Realtime faults and alerts helps enterprises to derive predictive maintenance strategies, improve on the customer services and maintain asset optimal performance.

Here are few benefits of connected assets:

- Remote condition monitoring of the asset for the critical faults or alerts.

- Predictive asset maintenance.

- Based on the realtime data, opportunity to allocate work order for service technicians at the site.

Conclusion

IT Managers and operation heads should consider operation life span of asset and plan solution considering asset operational life and maintenance. Contact us for a consultation on Enterprise asset management solution by visiting https://patterns7tech.com/enterprise-asset-management/. We helping our customers in the energy and precision manufacturing domains with digital transformation and solutions.

Recent Comments