Supplier quality inspection platform

Leading defence equipment and precision system manufacturer was looking forward the solution partner to automate Supplier Quality Inspection process and collect key data from the site.

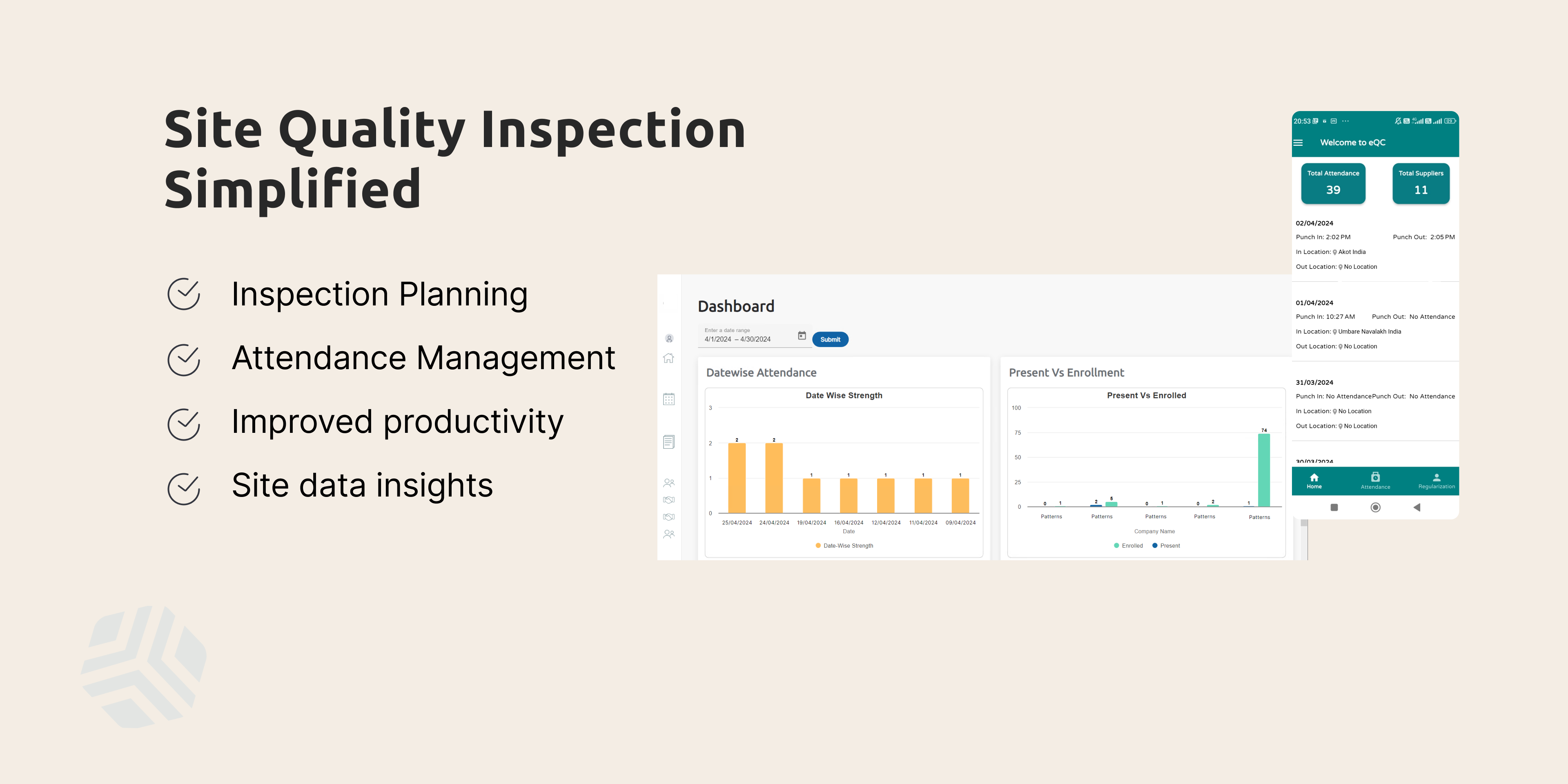

Patterns7 technologies has developed Quality Inspection platform for enterprise to track attendance, improve productivity and most important to bring key quality inspection data to the central database. This data helps to build different analytics and data insights to save cost and improve productivity.

Key Challenges

Customer has engaged different quality inspection agencies that deploy the inspection executives at the site and perform the quality check based on the checklist.

- Manually collecting site details and tracking the inspection executives is always challenging.

- Not availability of the attendance data has no control on effective manpower utilisation.

- Tracking and allocating quality inspection executives for the job is challenging.

Ready for process automation?

Solution

Most of leading enterprises has ERP implemented. Extending the ERP system is key challenge. With experience delivering the enterprise asset servicing solutions, Patterns7 team has integrated the ERP services.

- With service based architecture a strategic platform is set that can support Web as well as Mobile application.

- Customer can automate the inspection tasks and quality inspection executives book attendance from the supplier site with help of Mobile app.

- Quality data from the supplier site is collected at the database.

- Customer’s inspection department have centralized access and track different inspection work across region.

- Dashboard analytics helps to bring different data insights for the data driven decision.

Benefits of Supplier Quality Inspection automation

With intuitive dashboard analytics, inspection executive utilization is monitored resulting in the improved productivity and potential for the cost saving.

Scheduling and Tracking

Considering number of the Suppliers and work volume, scheduling and tracking become simpler with the platform.

Improved Productivity

Data Insights

With key site data and attendance details, helps to view quality inspectors utilization. Helping management for the data driven decisions.

Patterns7 working with clients in Precision manufacturing, Defence and Energy domains. Contact us for a consultation on Product Engineering services by visiting https://patterns7tech.com/product-engineering/.